How does Thermal spray powder work?

Thermal spray

coatings are made up of molten powder and wire burned with plasma or oxygen.

When thermal spray powder is sprayed on a mixture of metal, it forms a hard

coating. Thermal spray coating powder is used on vehicles, buildings, and other

structures. They defend the structure from chemical and weather components like

rain, severe temperature, moisture or humidity.

In thermal

spraying, materials are heated/melted and sprayed on the surface. They are

heated using electrical or chemical methods. Thermal spraying produces thick

coatings on the material. The coated materials like metals, polymers, ceramics

and other composites are applied in thermal spraying. Thermal spray powder suppliers use electric arc current or combustion to produce energy. Thermal spray

powder repairs damaged and worn-out parts of a machined structure. Thermal

spray coatings restore corroded parts of an object.

Types of Thermal Spraying Process.

Spray and Fuse

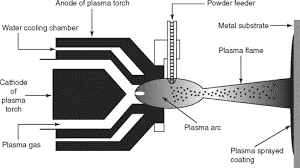

Plasma spraying

Flame spraying

Cold Spraying

How does thermal spray powder work?

Thermal spray

powder processes an extensive class of coating methods where the materials are

heated and sprayed on the surface. Thermal spray powder is used to coat

engineering components, protecting the structure from corrosion, high

temperatures and extreme weather conditions.

Thermal spraying

processes are extremely flexible and versatile. They can be used on any metal,

plastics, ceramics or composites. Choosing a suitable thermal spray powder is

essential. The shape and size distribution of thermal spray powder has a

notable effect on the quality of the coating. Dissimilar particle distribution

will lead to structural differences.

Process of producing thermal spray powder.

Atomization

Molten metal is

sprayed to build tiny droplets. These droplets dry and solidify into a powder.

Metal powders in the atomization process include iron, titanium, stainless

steel, aluminum, zinc, bronze, copper, alloys, nickel, and tin.

Chemical

Chemical techniques

involve dissolving oxides, calcining, and heat treating. Oxide-generated

powders have a soaked state because of the pores in particles. Thermal spray powder suppliers use chemical treatments to produce the

purest form of thermal spray powder. They have a high percentage level of purity.

Solid state reduction

In a solid-state

reduction method, the ore is mixed and crushed with other materials like carbon

and processed through a furnace, which forms a metal cake. The metal cake is

crushed into fine powders. This technique can take up to 3 days to produce

thermal spray powders.

Spray drying

Fine unprocessed

materials are assembled in the form of a water or solvent liquid base. These

liquid solvents are further sprayed into droplets through rotating wheels or

high-velocity gas. These droplets are evaporated by hot air or processed gas to

create fine particles. This technique builds free-flowing, spherical thermal

spray powders.

Conclusion:

Thermal spray

powder is applied on the material surface to protect the structure from

corrosion and extreme weather conditions. They build chemical resistance, high

or low friction, electrical insulation and lubricity. We have discussed in this

article how thermal spray powders are built and the techniques used to produce

them.

Comments

Post a Comment