A Quick Guide to Flux-cored Arc Welding

A

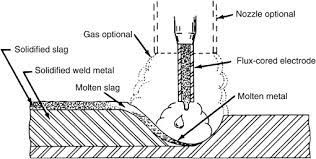

different kind of arcs welding technology is flux cored arc welds, which

employs disposable electrodes with flux within them. Many Flux Cored Wire Suppliers in India are available.

The

procedure is referred to as semi-automated or automatic arc welding. Metals

formation is caused by generating an arc across a constantly supplied electrode

and the ground metals. The flux in an electrode produces shields. An outside

provided neutral gas can either be utilized or not to provide further

shielding. That is, shielding gas is provided from an outside source, such as a

cylinder of gas or a protective flux wrapped around the placed electrode when

melted. Connect to the Welding

Electrodes Manufacturers for detailed information.

Programmes

FCAW

has a few particular uses as per Diffcor Suppliers:

As

we know that there are two types of flux wires in the market, but selecting the

correct one is important. Ask suggestions from Flux Cored Wire Manufacturers for the correct

one. This arc welding technique is very significant in the shipping industry

since it saves a lot of money on manpower.

It

is also employed in the welding part of several building businesses.

It

is frequently used in industrial sectors.

FCAW

is suitable for use on carbon dioxide, alloy, stainless steel, and composite

steels.

It

is employed in hard surfacing and resurfacing.

The

Functioning of FCAW

The

operation of arc welding with flux cored FCAW is simple and straightforward.

Despite other arc welding techniques that require either AC or DC power goods,

FCAW exclusively employs a DC electrical arc power source for the weld gun.

When the gun is hit within the constantly supplied disposable filler cable and

the piece of workpiece, an arc is produced. It forms the weld pool and bonds

when it solidifies.

Before

getting a flux wire, consult Flux Cored Wire Manufacturers.

The

benefits of flux drilled welding with arcs (FCAW)

The

following are the benefits of FCAW:

1.It

has several methods for delivering insulating gas.

2.It

may be used in any soldering mode.

3.Some

of its cables do not require shield gas since they are acceptable in stormy

circumstances.

4.It

has an increased likelihood of deposition.

5.Porosity

is quite unlikely.

6.Basic

metal requires little maintenance.

Negative

aspects

Considering

the numerous advantages of FCAW, certain drawbacks do exist. The limits of flux

cored arc welding in numerous uses are listed below.

It

generates slag that must be cleaned off after the welder.

1.It

generates more fumes, which is dangerous to the welder.

2.The

cost of the wire used

3.It

is more difficult and costly.

4.It

causes more splatter

That

concludes this essay, which examined the meaning, programmes, graph, machinery,

benefits and downsides of flux core weld (FCAW).

Comments

Post a Comment